Attaining Superior Finishes with In-Mold Decorations in Production

Attaining Superior Finishes with In-Mold Decorations in Production

Blog Article

Checking Out the Art of In-Mold Decorations: A Comprehensive Check Out Approaches and Innovations

When it comes to in-mold decorations, a marriage of creativity and precision emerges to redefine the opportunities of style. From the advancement of strategies to the arrival of innovative materials, the landscape of in-mold decors is a canvas where technology flourishes.

Development of In-Mold Decoration Techniques

The advancement of in-mold decor methods has actually considerably advanced the visual possibilities and effectiveness of product decor in manufacturing procedures. In the past, traditional techniques of enhancing products usually involved post-processing steps that were lengthy and included complexity to the production line. Nevertheless, with the intro of in-mold decor (IMD) methods, makers can currently seamlessly integrate attractive aspects directly into the molding process.

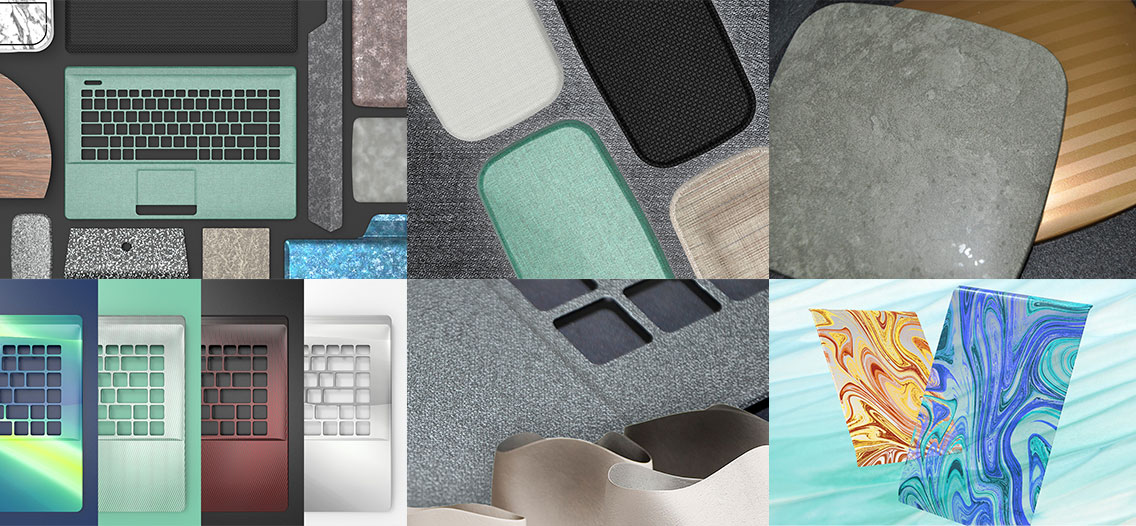

One of the vital advancements in IMD methods is the capability to achieve elaborate designs with exceptional detail and quality. By utilizing technologies such as high-resolution printing and progressed mold and mildew surface area therapies, makers can develop aesthetically sensational designs on products varying from consumer electronics to automobile parts. Additionally, IMD methods have actually made it possible for the incorporation of textures, coatings, and shades that were previously tough to attain with typical design methods.

Advanced Materials and Technologies

Advancing the leading edge of technology in production, the assimilation of sophisticated materials and modern technologies has actually transformed the landscape of in-mold decor techniques. Advanced products such as unique polymers and nanocomposites offer enhanced sturdiness and visual homes, enabling vivid shades and detailed styles to be included flawlessly into the final item. These materials also supply enhanced resistance to environmental aspects like UV radiation and chemicals, enhancing the durability of the decorations.

Technical advancements, such as digital printing and 3D surface area texturing, have additional expanded the opportunities in in-mold decorations. Digital printing makes it possible for high-resolution graphics to be directly applied to the mold and mildew surface, causing sharp images and specific details. On the other hand, 3D surface area texturing strategies develop responsive results that boost both the sensory and visual charm of the decorated products.

The synergy in between innovative products and technologies not just raises the appearances of in-mold designs yet additionally enhances performance in the manufacturing procedure, making it much more cost-effective and eco-friendly (In-Mold Decorations). This integration leads the way for limitless creative possibilities in the world of in-mold decor

Intricate Style Opportunities

Checking out the world of in-mold decorations introduces a world of intricate layout opportunities that press the borders of creativity and precision. Producers are no longer limited to simple patterns or styles; rather, they can currently attain very detailed and complex decorations on their products. In-mold design techniques enable the unification of great lines, detailed appearances, and vibrant colors that were formerly challenging to accomplish with various other techniques.

Among the crucial advantages of in-mold designs is the capability to create 3D results, adding deepness and realistic look to the layout. This technique opens up a large range of creative opportunities, enabling manufacturers to reproduce all-natural materials like timber grain or marble with amazing accuracy. In addition, in-mold decorations can be made use of to produce one-of-a-kind surfaces such as metal results or shiny textures, enhancing the general visual appeal of the item.

In addition, in-mold decorations provide excellent precision, guaranteeing consistency in style across a large production run. This degree of detail and accuracy is important for markets where branding and design honesty are critical, such as in the auto or consumer electronics industries. On the whole, the detailed style possibilities managed by in-mold decors continue to transform the way products are embellished and made in different markets.

Market Applications and Innovations

Building upon the intricate style opportunities facilitated by in-mold decorations, different markets are using cutting-edge applications to raise item aesthetics and performance. In the automobile industry, in-mold decorations are being utilized to create visually appealing exterior and interior components with complex structures and patterns. This not only enhances the overall look of lorries however also contributes to a glamorous feeling. Additionally, the customer electronic devices market is leveraging in-mold decors to generate modern-day and sleek gadgets with smooth designs that integrate switches and displays into the product surface. This results in a much more straightforward and aesthetically pleasing final result. The family home appliance market is incorporating in-mold decorations to improve the look of home appliances such as refrigerators, stoves, and cleaning makers, making them more aesthetically appealing in contemporary home setups. By welcoming Read Full Article in-mold decors, these industries are setting brand-new criteria for product design and appearances, giving consumers with ingenious and aesthetically striking items.

Future Fads in In-Mold Decorations

Accepting progressing innovations and layout methodologies, the world of in-mold decors is poised to witness significant changes and innovations in the future. Among the crucial future trends in in-mold designs is the increasing combination of smart innovations. This includes the incorporation of features like interactive displays, LED lighting, and even check my site clever sensors directly right into the molded components. Such improvements not just improve the visual allure of the items yet additionally add functional worth, making in-mold decorations much more than simply a design aspect.

Furthermore, sustainability is coming to be an important emphasis in the area of in-mold decors. Producers are discovering green products and processes to decrease ecological influence while keeping top quality requirements. This fad straightens with the expanding customer need for sustainable items, pressing the market towards more environmentally conscious techniques.

Furthermore, customization and personalization are expected to play a significant duty in the future of in-mold decors. With improvements in digital printing technologies and software program capabilities, makers will certainly be able to provide more customized remedies to meet private client preferences. This fad is most likely to drive advancement and creative thinking in the style and manufacturing processes, offering one-of-a-kind and individualized products to consumers.

Final Thought

In-mold decoration techniques have actually progressed dramatically, providing sophisticated materials and modern technologies that make it possible for elaborate layout opportunities. These innovations have actually found applications throughout numerous markets, causing constant improvements and future patterns in in-mold designs. The art of in-mold decorations remains to push borders and produce brand-new possibilities for improving item appearances and performance.

Building upon the elaborate style possibilities promoted by in-mold decors, various sectors are harnessing innovative applications to boost product aesthetics and functionality. Furthermore, the customer electronics market is leveraging in-mold decorations to produce sleek and more info here contemporary tools with smooth designs that incorporate buttons and presents right into the product surface area. By embracing in-mold decorations, these sectors are establishing new requirements for item style and aesthetic appeals, providing customers with visually striking and cutting-edge products.

Report this page